Shotgun shells have gone through a significant transformation in the last century. Federal Cartridge Company celebrates its 100th anniversary, a century that included several shotshell milestones.

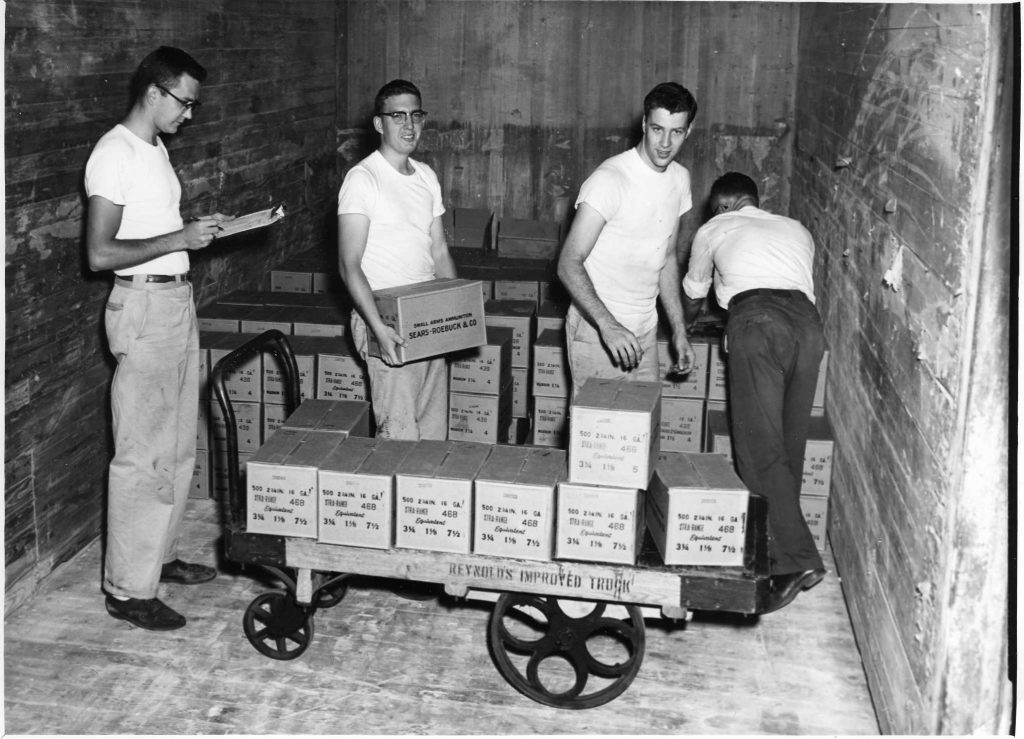

It all began humbly in 1922, when Charles L. Horn took control of a three-year-old fledgling ammunition manufacturer. Knowing he faced fierce competition from a pair of established ammo companies, he embarked on a novel strategy. Horn worked to get Federal products—which at the time consisted only of shotshells produced in a 9,000-square-foot factory—onto the shelves of barber shops, gas stations, and grocery stores. He also established a contract to sell Federal Ammunition through Montgomery Ward & Co. and Sears. The strategy worked and helped the company grow. In 1941, Federal secured a contract worth $87 million from the U.S. government to build and operate the Twin City Ordnance Plant in Arden Hills, Minnesota, which was a critical contributor to military ammunition and other defense products during World War II, the Korean War and the Vietnam conflict.

A shotshell is a cylindrical, or straight-walled, cartridge used strictly in shotguns. Historically, shotshells were loaded with small pellets, but many projectiles served as the payload. A shotshell is fired through a smoothbore barrel with a tapered constriction at the muzzle, better known as a choke, that dictates the pellet distribution. A shell can also contain a single, solid projectile referred to as a slug, usually fired through a rifled slug barrel.

The first shotshell cases were brass, like a pistol cartridge, and by 1900 the cases were made of paper. Eventually, a plastic tube was mounted on a brass base that held a primer and became the standard. The tubes held the pellets contained by a wad, and the end was crimped or folded closed.

The size or caliber of the shotshell is known as its gauge. 12-gauge shotshells are the most popular, but there are also 10, 16, 20, and 28-gauge and .410 bore.

In the 1870s, paper hulls started to replace the reloadable brass hulls. It was the start of a trend for convenience over reusable products.

Wads

The wad in a shotshell plays an important role. The pellets need to be contained and prevented from mixing with the powder. In the early years, card, felt, leather or cork kept the payload snuggly in the tube. Engineering took wads to a new level with the introduction of steel shot.

The wad in modern shotshells protects the barrel from the steel pellets. The wad acts as a protective sleeve to carry the pellets through the length of the barrel. Steel and other hard non-toxic options are not malleable and do not constrict through a choke. The wad now plays a vital role in pellet spread and pattern.

Black Cloud shotshells are a great example of modern technology used to improve performance and hunter success. They work flawlessly in various chokes, including ported, full and wad-stripping. The specialized wad in Black Cloud shotshells has rear-deploying brakes that spread out to release the shot in a perfect and dense pattern. The new technology is known as Black Cloud FLIGHTCONTROL FLEX.

A modern wad serves several functions and includes the powder wad for a gas seal, the cushion, and the shot cup, which may be separate pieces or be one part.

Paper vs. Plastic

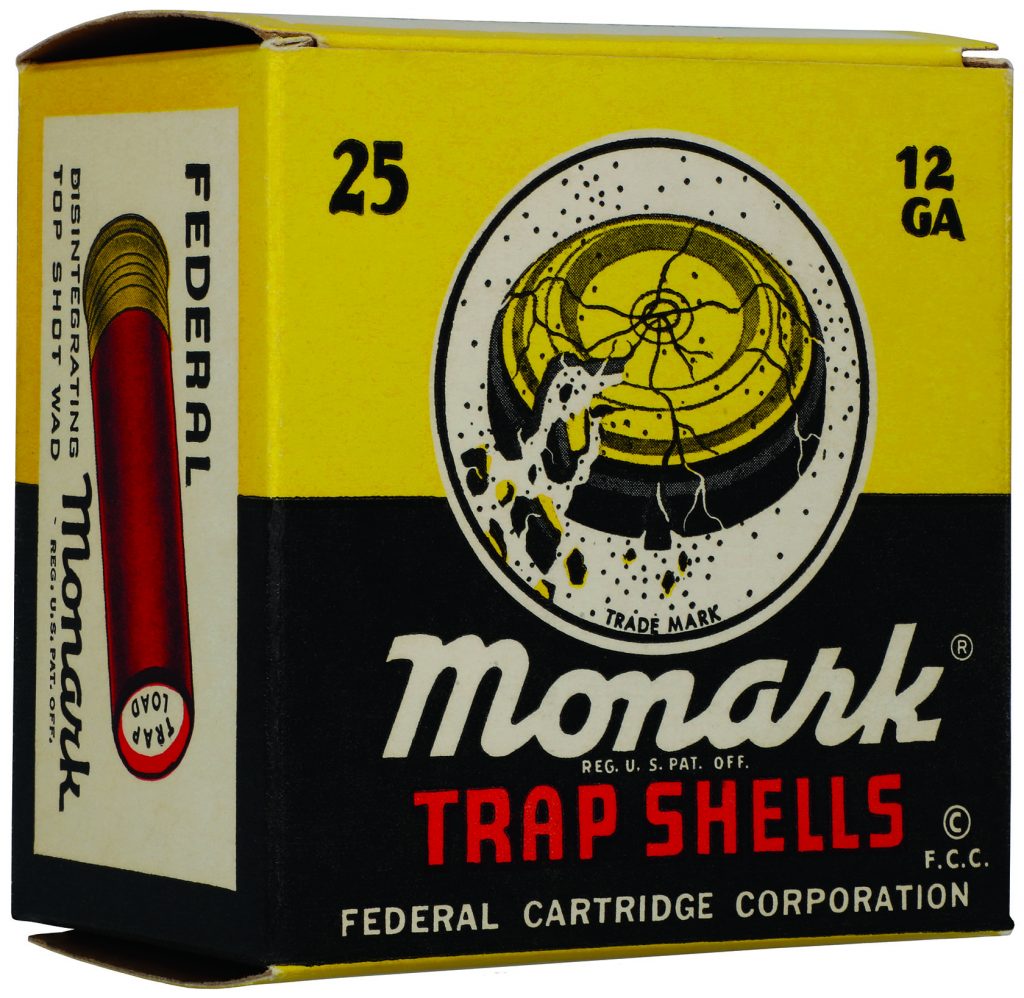

Paper hulls were the first tubes used in mass-produced shotshells. The paper was wound tight to provide structure and support. The hulls were waxed or varnished for some degree of waterproofing. Extruded plastic hulls were a new and novel idea that ammunition companies slowly introduced in the 1960s. In 1973, the Federal catalogs highlighted Champion paper hull and Champion II with plastic hull shells. The benefits were noticeable, and today plastic is the primary material of shotshell hulls. Federal has strived to make the hulls biodegradable to ensure they are environmentally friendly.

Primers and Powders

The primers on these early shotgun shells were identical to pistol primers of the same diameter. The pistol primers worked well with the powders used, but new powders required new primers. Modern smokeless powders are far more efficient than the original black powder used in shotgun shells and require little space in the hull. A modern shotshell has small quantities of double base powders, equivalent to quick-burning pistol powders, with up to 50% nitroglycerin.

The primers on the paper hull shotgun shells were the start of a new ear, and the new primer contained both the priming charge and an anvil, making the shotgun shell primer taller.

Brass

Modern plastic shotgun shells bases have a thin brass plated steel covering. Early shotshells used solid brass. The modern versions are lighter and more economical to produce.

The brass base often dictates the type of load in the shotshell. Lighter loads have “low brass” shells. The magnum or more powerful loads have “high brass” extended up farther along the sides of the shell.

Defense

Federal Cartridge Company started with the hopes of obtaining military contracts to make shotshells. The modern shotgun defense loads are sold as a PREMIUM PERSONAL DEFENSE SHOTSHELL. The modern offerings include .410 handgun loads that maximize the firearm platform potential and provide lethal close-range patterns and pellet penetration. The Personal Defense line uses a specially formulated propellant, FLITECONTROL Wad, and a specialized payload.

Copper plated, high consistency buckshot in 12-gauge 2¾-inch 4 Buck, has 34 pellets. Shot through an improved cylinder choke at 5 yards, the load’s unique wad configuration is designed to produce a 5-inch pattern at 15 feet—the ideal for in-home defense.

Federal makes 10-, 12-, 16-, 20-, 28-gauge, and 410 bore shotshells. The company was the first to color code by gauge, which continues as an industry safety standard.