There are many options when walking into an archery shop and grabbing a box of new arrows. Finding the right arrow quality means a quick look at the reference chart on the box, allowing for swift decisions. However, the right arrow is not always the perfect arrow.

As technologies advance with compound bows and crossbows, new arrows with different diameters and components should now make hunters take a second look. Bowhunters need to consider shaft diameters or even tapered arrows and different materials. The varied options on the shelves today provide improved penetration, kinetic energy, and trajectory. Suppose you have not considered arrow construction, weight distribution, flight, and resistance to wind and obstacles. In that case, you may be surprised by the latest advantages in the archery scene.

Choosing the best arrow for the task is how any archer should approach shopping and make informed decisions. With distinct advantages for different hunting situations including, style, habitat, and wildlife species, hunters looking for the best advantage will have more than one or two arrow options in their quiver.

Do Not Settle

The average deer hunter uses basic equipment, with the thought that they shoot most deer at less than 30 yards. Why would you use anything but a standard 6.5-mm carbon arrow?

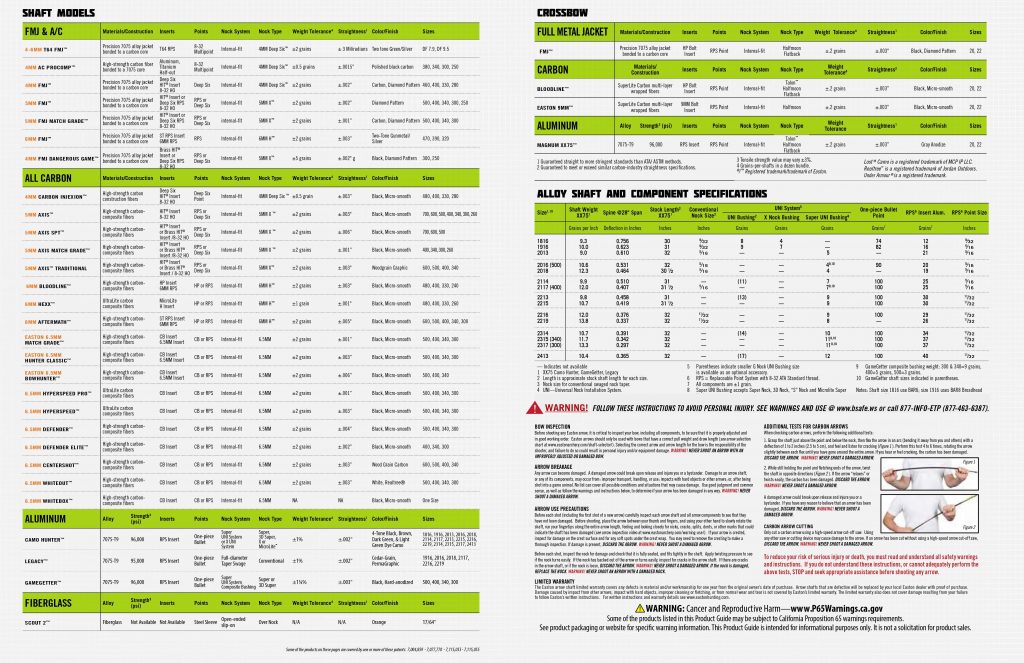

Anyone that has bow hunted for any length of time knows that a perfect shot is not always possible. Sometimes an arrow will hit bone, or the hunter is forced to shoot at a challenging angle. In these cases, consider shaft diameter. Small diameter arrows offer increased penetration with less resistance or friction. Easton Archery offers smaller-diameter arrows in 6, 5, or 4 mm, which will ensure you bring home the venison. Thin arrows provide the millimeters of clearance sometimes needed to clear obstacles and offer greater stability when the wind blows or the rain and snow try to dampen your enthusiasm.

Tapered

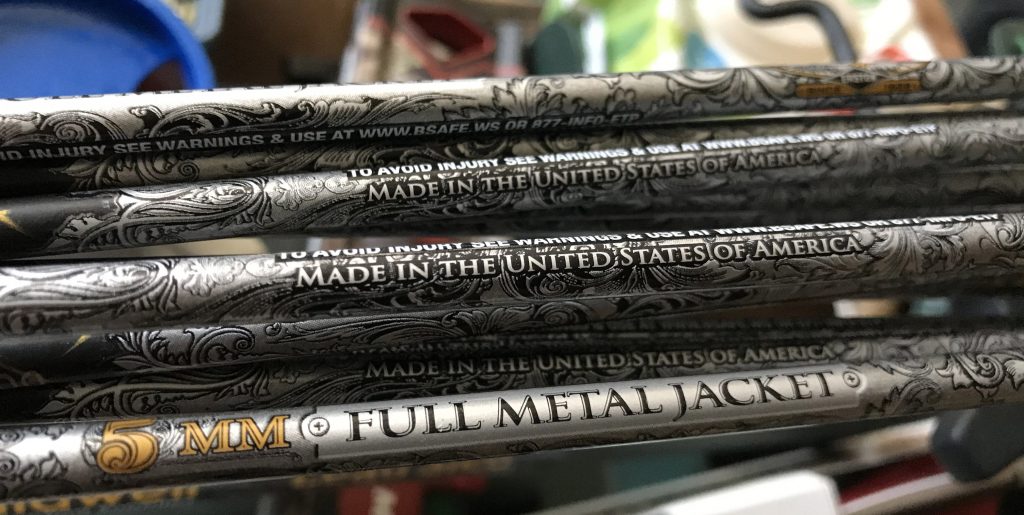

Easton continues to find new ways to increase arrow performance and reduce wind drag. One of its latest innovations is a tapered shaft, which maximizes front-of-center (FOC) weight for better accuracy. The Easton T64 seamlessly tapers from 6 mm at the front to 4 mm at the back, resulting in 30 percent more weight FOC, even before the broadhead is attached. This specialty shaft also features a full-metal jacket, further increasing the weight for even better kinetic energy and penetration.

The advantage of weight distribution and an FMJ that tapers to the nock provides several benefits over a standard arrow. More weight at the front of the arrow makes it fly more consistently and accurately, making for more precise arrow placement and better penetration. The tapered back end reduces drag and is less susceptible to wind.

It is easier to steer the arrow with the weight up front instead of pushing it and keeping a straight and accurate trajectory. Race cars are designed with the weight forward and a slim tail to gain an advantage in speed and aerodynamics. Archers can now use the same theories and technologies to be more successful on any archery hunt.

Aluminum Advantage

When we shot aluminum arrows in the old days, they were removed from targets easily. Most shooters did not even own an arrow puller. Aluminum has a consistent, smooth surface with reduced friction, making it easier to remove from modern targets. Take the test by shooting a carbon shaft into a target, followed by an aluminum one, and you will see that the aluminum arrow penetrates deeper yet is easier to pull out.

Today’s archers have the best of both worlds in a carbon shaft wrapped with aluminum. The aluminum exterior generates less friction, increasing viscosity when flying through an animal’s fat and body fluids, thus providing better penetration. The combination of aluminum and carbon adds weight to the entire shaft, which increases the kinetic energy and penetration. Easton’s FMJ (Full Metal Jacket) was one of the first aluminum-wrapped carbon arrows to feature this advantage. The FMJ advantage should be considered when looking at any arrows. The aluminum jacket is available on different diameters and even a tapered shaft.

An FMJ arrow has more weight than a standard arrow, increasing kinetic energy and penetration. The advantages stack up quickly when you start looking into technologies that favor the hunter.

Straightness and Weight

Like buying cartridges and bullets for a rifle, arrows come in good, better, and best. The ‘premium’ arrows will be the straightest, as indicated on the shaft in thousandths of inches. The overall arrow weight tolerance is expressed as grains. It is easy to determine that lower listed numbers mean straighter arrows and higher prices. The straighter the arrow and more consistent the weight distribution, the better they should fly. It follows then that the more consistent the arrow, the more precise the arrow placement can be.

Hunters that understand how little things add up will know that consistency in shaft straightness and overall weight means arrows fly with the same force and motion every shot. Straightness measurements range from 0.006 to 0.001 inches. If there were an arrow with 0.000 tolerance, it would be perfectly straight. Arrows with the lowest tolerance are the straightest and should shoot the most consistently and accurately, which is why they come at a higher price tag.

Weight tolerance measurement should also be considered, as it shows how close the arrows are perfectly matched. Weight differences within a batch will cause inconsistent arrow flight out of the bow.

TenPoint, Pro Elite 400 Arrows with Easton carbon shafts are an excellent example of quality arrows, straight to within 0.003 inches and are weight-sorted by hand to within 2-grains of each other, per box. Testing the arrows at the range, we shot three arrows from the same box through a chronograph with a TenPoint Nitro XRT. The chronograph measured three duplicate shots at 420 fps. The consistency was evident in a one-inch group at 50 yards. Arrows of less straightness and weight, shot under the same control and conditions, produced a variance of 14 to 32 fps with three arrows. The test makes it easy to see why the little things in arrow quality do matter.

Backbone

The spine is the measure of the stiffness of an arrow, from tip to nock, and its resistance to bending. The amount of flexibility is determined by the amount of energy being transferred from a bow or crossbow. An arrow with lots of spine will not flex much but will handle the energy transfer from the bow consistently. An arrow with insufficient spine could shatter from an overdose of energy.

Arrows are available in a wide variety of spine. The draw weight of a bow will determine the spine required. With some crossbows shooting close to 500 fps, arrow manufacturers have kept up with new and current demands to ensure performance and safety.

Dynamic spine measures how much an arrow bends when fired from a bow or crossbow. Influences include static spine, string force, fletching weight, and nock weight. An arrow should bend and flex to some extent during flight. That flexing and bending influence accuracy and consistency.

Compound bow and crossbow manufacturers have recommendations for spine for specific draw weights and models. You can usually find a handy chart on the arrow box or bow instructions to help determine the required stiffness of an arrow for specific draw weights with a given bow.

Arrow Code

If you have been flinging arrows for years, you will remember the old letter codes S, H, X, and G for shaft size. Easton used the letters to indicate the internal diameter of arrows and match compatible inserts and components. Today, the internal diameter of all modern performance hunting shafts is now expressed in millimeters.

Easton’s S code (standard diameter) is now shown as 6.5 mm, H (reduced diameter) is 6 mm, X (micro diameter) is 5 mm, and G (ultra-micro) is 4 mm. The millimeter codes allow archers to compare one size to another immediately and make it easier to select the right components for a specific arrow. Note that some manufacturers still use imperial measurements. In contrast, others use the outer diameter to denote the size, so keep that in mind when comparing different arrows.

Dr. D Full Synthetic Arrow Lube

Easton offers Dr. D Full Synthetic Arrow Lube to ensure easy arrow extraction from targets. The formula is scent-free, easy to apply, and is effective for all types of arrows. The bottle comes with a quiver-mount neoprene sleeve to ensure you always have the lube when headed to the range.

SEVR AP 1.7 Broadhead

A premium arrow requires a premium broadhead for maximum benefit. The AP 1.7 features a steep blade angle for increased penetration, this all-purpose broadhead creates a 1.7-inch cutting diameter, with the stainless-steel blades locking open on impact to pivot around bone (the blades can be locked down for practice shots). Built on a machined alloy ferrule, the AP 1.7 comes in 100 grains with standard 8-32 threads.

SPEED BAG 500

The Speed Bag 500 is designed to endure crossbows and vertical bows shooting high-velocity arrows at up to 500 fps, not only stopping them but also reducing penetration. Removing the arrows with one hand is easy, and the generous, 24-inch square target face includes graphics on both sides for dispersing shots.

binance kod

July 20, 2024 at 6:06 am

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Бонус при регистрации на binance

August 17, 2024 at 4:13 pm

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.